How AI Reshapes Supply Chain Management

Watch the episode

Maciej Kłodaś (MK): Hi everyone, welcome to season two of C&F Talks. My name is Maciej, I’m the leader of analytics experience at C&F and we’ll be talking about our challenges, ideas and trends from the perspective of an IT partner. Be sure to subscribe, like and comment because we would like to hear your feedback.

My guest today is Piotr Sosiński. Hello Piotr.

Piotr Sosiński (PS): Hi Maciej.

MK: Tell us what is your responsibility at C&F? What do you do?

PS: I’m a senior delivery lead and I’m responsible for manufacturing and supply chain area.

MK: Two years ago, I’ve been on a Gartner conference and AI was all over the place. Gen AI to be more specific, and this was the buzzword in every industry. Everybody was implementing AI, mostly chat GPT in areas like, optimizing or automating their everyday tasks.

It’s two years later. Tell me, is this still a buzzword in the area of supply chain or is it really getting practical in terms of implementing the processes with AI in mind?

PS: AI is no longer a buzzword or a futuristic concept. It has become a critical enabler for improved performance and resilience. And what used to be considered as optional tool, now is a necessity, if you would like to improve our efficiency, reduce cost, manage risks better or improve our customer satisfaction looking from the supply chain perspective.

In fact, at recent Gartner conferences, AI is still the main topic and even up to 90% of the sessions are AI focused on its practical application and in real world process optimization. That means that there is a clear shift in the industrial consensus that AI is reshaping the supply chain.

AI has been reshaping supply chain for some time, but right now the process is accelerating. And if organizations would like to tackle challenges like demand volatility, or capacity constraints, or global disruption, AI can provide solutions and provide them with far greater agility.

MK: Okay. So let’s talk about the main challenges in supply chain. What AI can help optimize?

PS: There are multiple challenges in supply chain. It’s a very broad and complex area, but today I would like to cover three main topics. One is the overall supply chain complexity and how AI can address that. Second is supply chain sensitivity and vulnerability. And the third one is lack of multisensing integrations. Okay.

MK: So let’s start with the first one. Can you explain, because I know something about supply chain, but these expressions are new to me. What does it mean modern supply chain network complexity?

And can you give some examples, maybe a use case?

PS: So modern supply chain network reflects business processes and the business processes are global and usually very complex. What it means is: it impacts end-to-end visibility and hinders data-driven decision-making. Usually it includes multiple providers, partners, suppliers, distribution channels.

It means that supply chain network needs to adapt to demand volatility, to geopolitical situation, environmental pressures, security risks, and regulatory requirements. So there is plenty of external factors that are impacting the overall supply chain and all of them need to be considered to be able to manage operations and improve KPIs that supply chain operates on.

MK: So they need to be controlled. Right now, if I remember, the main problem is that none of them or little of them are centralized in terms of control. They are spread across the company.

Controlling each of these elements and optimizing how they work together is a big challenge at the moment. So do you have some examples or have you been working with your clients in building such complex tools that will gather all of these elements in one place as a control room kind of thing to see and monitor all of these factors in one place?

PS: Exactly. One of the traditional solutions to this complexity is a supply chain network control tower. Historically, a control tower would gather data and it would be siloed data that is put together in a single dashboard or a report. The data would be tracked passively and then aggregated into the overall decision cockpit.

Through the last years, the control tower solutions in supply networks got improved. Additional analytics, advanced analytics has been enabled. It allowed to move from reactive management into more proactive identification of patterns and early warnings.

But right now with the fast moving world, and as I said, multiple external factors that are impacting our supply chain network and decision making, that’s not sufficient. AI provides great opportunity to improve the overall management and the way the control towers are built and constructed.

MK: So I understand that instead of people monitoring the data, analyzing this manually, we are utilizing AI algorithms to identify patterns, identify anomalies in the supply chain and proactively feeding the control tower and informing in a timely manner the operators in the factory that something is going on and you need to react.

PS: That’s correct. Control tower cannot monitor and only focus on monitoring. It needs to do more. It is expected to mentor operations.

So instead of showing data, it should guide users through the process, provide context or recommendations and clear next step of actions for the users. So it means it requires embedded AI logic and machine learning that provides rule-based automation to the classic supply chain control tower implementation.

MK: So from what you’re saying is that basically we have some scenarios that in the past have been driven by people. And now the same thing is implemented into AI and AI identifies certain factors, certain signals from the factory. And then based on those scenarios, it’s recommending next best action for the factory operator.

PS: That’s correct. That’s exactly the case. So AI can support an integrated exception-based logic in the supply chain systems and provide and train models to distinguish between those false positives versus mission critical issues.

So it provides additional layer of automation that’s based on internal company business processes and the workflows. And based on that, it can guide informed decision making.

MK: Is this the moment where AI can make autonomous decisions in this control room or still the operator has total control over the process?

PS: That’s a very good question. And that’s one of the main concerns usually our clients have, whether AI will start hallucinating and making bad decisions even if the input data is correct. In our solutions, we ensure that we’ve got this human-in-the-loop assurance.

That means that the key decisions, even though they are fed by the AI-generated signals, but the key decisions and final approvals are made by users. That means the human factor is still in control.

MK: All right. So let’s talk about other challenges. So you said sensitivity and vulnerability, right? What does it mean? Well, I can imagine what it can mean, but can you explain what does it mean in terms of supply chain and what are possible solutions where AI can help?

PS: Sensitivity and vulnerability is the second key challenge for current supply chain networks. We live in very complex times and our operations, supply chain operations are fairly optimized, as much as currently possible. That means that a shortage of a single inventory item can cascade into production delays that would require coordination across multiple business processes.

Supply chain networks are sensitive to changes in demand, supply, or external factors, as we mentioned. That can be political, that can be environmental, or cyber threat-related. At the same time, it’s expected that decisions to supply chain are made immediately and they are informed. So how can we prevent the sensitivity and vulnerability or support immediate and accurate decision-making?

And again, AI comes in very handy in this area. We can introduce AI-driven copilot assistants that can help users in their daily work. How does it work? Imagine you have organization’s own AI assistant that’s fed on the enterprise data, that understands business logic, that has workflows incorporated, that understands business cycles, that considers policies or even escalation chains. It should have a conversational interface. That’s a thing that AI introduced.

So it’s no longer a locked list of items or topics that users can address, but it has an open NLP-driven interface that you can communicate with via natural language. So you can ask open-ended questions, considering predefined topics, and then AI will support you and have like a conversation with you and will provide you with additional inputs, will flag risks, detect disruptions in the datasets and provide you with particular input along with proposed solutions to the highlighted problems.

MK: So it’s more than an agent, right? It’s more complex than something like an agent. It’s a very complex decision tree with a conversation interface, something that is a mentor to you and can help you guide through the process and optimize the way you work and make decisions.

PS: That’s correct. That’s exactly the case. It can replace days of analysis that users would normally do in a classic way with instant insights that accelerate informed decision making, that would reduce the cognitive overload of the users where they need to consider a lot of different sets of information coming from across different channels.

AI can do it for them. And then in that conversation provide additional information, as I said, provide proactive alerts, impact analysis, as well as proposed solution or remedies to the highlighted problems.

MK: So it’s also a tool for mitigating risks because, you know, human errors, not knowing certain policies, just making mistakes. We have something that protects us from making human errors, right?

PS: It can fix human errors. It can support repetitive routine tasks. It can slice through the data fast. So the time needed to analyze inputs and make a list of actions is then limited to almost real time.

MK: Do you have any real life use cases for implementing such solutions?

PS: Yes. In our company, we are currently working on this kind of AI assistants. We provide them to our customers. And as I said, it’s based on the cognitive interface and NLP-driven queries that replace manual reporting.

MK: But as I understand, the concept is the same with every kind of supply chain, but due to the fact that there are different security policies, different data compliance, the processes are different. Also, we need to tailor this approach to each case differently, but the framework is essentially common.

PS: Yes, that’s exactly the case. Each case is treated individually. That means we tap into enterprise data or align with our business partners and clients. What kind of information should be fed to our assistant and what kind of output is expected? Because it may vary depending on the scale of a client company or the area of operation.

MK: And the third challenge, what about that? Can you elaborate on this one?

Thanks for being with us, guys. Share, subscribe and like our content. Leave your feedback. We really like to know your thoughts about how we do and what you like to see next.

PS: Yeah. So the third thing is lack of multisensing integration. And in modern supply chains, lack of multisensing integration refers to the failure to combine diverse data streams from very different areas.

To give you an example, we can talk about IoT data from the sensors. We can talk about GPS. We can talk about various information that’s coming from our suppliers, environmental data, like weather conditions or logistics platforms. And ideally, you would combine all of those data streams into a cohesive real-time view.

MK: And what does this real-time view gives us? Is it assessing what would be the impact of all of these factors given or is it only our monitoring thing? How does it work?

PS: Before I go into the works of the system, I would like to focus a bit on the issue, right? So we talked about combining multiple data sources and very often companies have it done partially or they don’t have it at all. That means the data is siloed or inconsistent or unavailable.

And that means companies have very limited situational awareness. And based on that, they make slower and less accurate decisions. And let’s take shipments monitoring as an example, right? Lack of multisensing integration means very often that we have isolated data sources. We communicate with our suppliers in the old-fashioned way. That means emails, charts, or even spreadsheets being sent back and forth.

That means we have blind spots. We don’t have real-time data from sensors. So the view we have is very delayed and very often as a result, we don’t know where our shipment is, if it’s delayed or not, if there are any risks that it will be on time or not.

MK: So it’s a problem with timely communication between different areas of responsibility and optimizing the decision-making process based on the input of data that we already have in the company, but we can’t really connect the data with each other.

PS: We can have the data like our IoT sensors, or we can get it from our suppliers, or it’s available like weather condition portals. That’s an external factor that we can also use in our IT AI models to highlight the risks and build a modern system to monitor the shipment status live.

MK: Okay. But you can’t really have it all together to see what are the patterns between all of them and what is the impact of one on the other.

PS: That’s correct. Putting all those datasets together and applying AI assistance means that we can integrate structured data like logs from our supplier systems and unstructured data, like those emails from also other suppliers, and then supplement it with additional data streams like GPS data, like IoT data, like weather conditions and other streams to maintain continuous visibility and then detect those details and risks earlier and then gauge potential impacts. AI can also help to prioritize those risks or issues and sort it according to a given logic and provide recommendations. In short, it can transform scattered signals into a unified intelligent tracking solution.

MK: Okay, sounds like an optimization to me. Imagine that I am the leader of an area in supply chain and I’m on the very beginning of the road of digital transformation of my own business. What would be your recommendation? Where can we start and how the process should look like to identify where the area of optimization is? Which tools do we need to implement?

PS: That’s a very good approach. First of all, we need to understand the needs of our client because we discussed only three key issues, but supply chain is a very broad chain of processes and areas and AI can help in very different ways.

So on top of the examples we just discussed, it can help with more intelligent demand forecasting, autonomous inventory optimization. It can help with suppliers, risk management, smart logistics and routing. It can also help with traceability using technologies like blockchain or can be used to support predictive maintenance. So the list of use cases is very, very large and depending on the needs of our clients, we can tailor our solutions to those particular areas and then start with the process.

Now, how the process would look like after the initial discovery, probably we would support build of particular use cases, then apply a prototype, collect feedback from this exercise and then pilot the solution. And then once pilot is approved, expand further across whole supply chain, whether it’s factories or distribution centers or all the nodes in the supply chain.

MK: Okay. So your recommendation is to start small, identify the areas where the friction is high, where the value would be the best, the highest from implementing AI. And then after getting the value from the first pilot, we can expand to different spots to add an additional element with AI implementation and build a certain roadmap. So this would be a multi-year long program, a true digital transformation.

PS: That’s correct. And that’s why it’s important to start small and expand further. There is a couple of risks and concerns usually our business customers have that are related to AI. I’ll list them in random order. One, the cost, right? So if you’re thinking about AI implementation globally at large scale upfront, that means probably high budgets. And usually the decision makers are hesitant to invest that much. So you start small, you show the value, and then you can expand because you get better budgets. That’s one risk that’s addressed.

Second one is actual improvement that AI can give is related to the data quality and data availability in the companies. And that can be addressed with the solutions. For instance, we, as C&F, have an in-house data cleansing solution and automated solutions to gather and unify data that’s available for the models.

Third risk, and this is something I highlighted earlier, is the lack of control over AI. And here the solution is to have this human in the loop kind of approach where AI models provide recommendations. They analyze the data, but at the end of the day, there is someone, a human being, a skilled user or subject matter expert that approves the plan that AI provides. So in that case, we are secure, we take benefits from AI, but then we are still as human beings in control of the process.

MK: And what is the attitude of your stakeholders when you are talking AI? Are they hesitant or in doubt? Are there any blockers from different stakeholders across, because from what I understand, it’s not only implementing AI in one place. You need to cooperate with different stakeholders because the AI element will impact all other elements in the whole supply chain.

PS: Yeah, that’s a very good question. So the feelings are mixed. It depends on the appetite for innovation. Some of them have more innovative mindsets and they are open. Some are a bit reluctant, but we have to remember a couple of things. First, AI is here. And if we want to keep our competitive advantage as a company, whether we are manufacturer or only distributor, we have to think about AI and its implementation.

Second reason that business partners are highlighting is they are afraid that AI will take away their jobs, right? And we have to remember that AI is here not to replace supply chain professionals, but to support them and provide them with the insights, take care of routine tasks, time-consuming tasks, and unlock their time for more value-added activities, for networking, collaboration, and move from the vicious cycle of continuous firefighting.

With the right tools, accurate and properly integrated data, and this willingness to embrace change, those organizations can unlock their potential, be successful. So it’s not about building supply chains that can replace people. It’s not about just efficiency, but it’s more about building supply chains that can predict, adapt, and thrive in this increasingly uncertain world.

MK: One last question at the end. What is your take on the adoption of AI in supply chain? What do you think will be the next big thing when implementing AI in your area with your clients?

PS: It’s a very good question. It’s a tricky question because the situation on the market is dynamic. We have new models coming in with new capabilities, so we always need to stay in touch with the newest technologies and then think how to reapply that for our clients to bring in them value.

Personally, I believe the implementation of those cognitive models, where you can have open conversation with, will be more and more popular because they will be becoming more like a human being in terms of collaboration and bidirectional communication. And I think that will be a huge boost to efficiency, but also an enabler for the companies to grow.

MK: Great. Thank you very much Piotr for being here.

PS: Thank you guys.

MK: Thank you. Please like, comment, and subscribe. Leave us your feedback. We would really like to know your thoughts about how we are doing. Do you like our content and what would you like to see next? And hopefully we see each other in the next episode of C&F Talks.

The critical role of AI today

Our discussion highlights how AI has shifted from futuristic idea to essential tool for tackling volatility, capacity limits, and global disruptions. It’s not just about efficiency; AI in supply chain management is now central to risk management, cost reduction, and customer satisfaction. Industry consensus is clear: at major Gartner events, up to 90% of sessions now focus on AI’s real-world impact in supply chains. The biggest challenges to tackle right now include the complexity of supply chain operations, sensitivity and lack of resilience, and the failure to generate insights based on all available data.

How to make AI in supply chain work

Implementing AI is a multi-year journey. Our experts recommend starting small, focusing on high-value use cases, and gradually expanding. Key risks: cost, data quality, and trust, can be mitigated with a staggered approach and “human-in-the-loop” oversight. Importantly, AI is not replacing professionals but empowering them, taking over routine tasks and freeing experts to focus on collaboration and growth. The future lies in cognitive models; advancements in this area are already enabling more human-like, conversational interactions with enterprise systems.

Unlock the potential of your data with our AI expertise

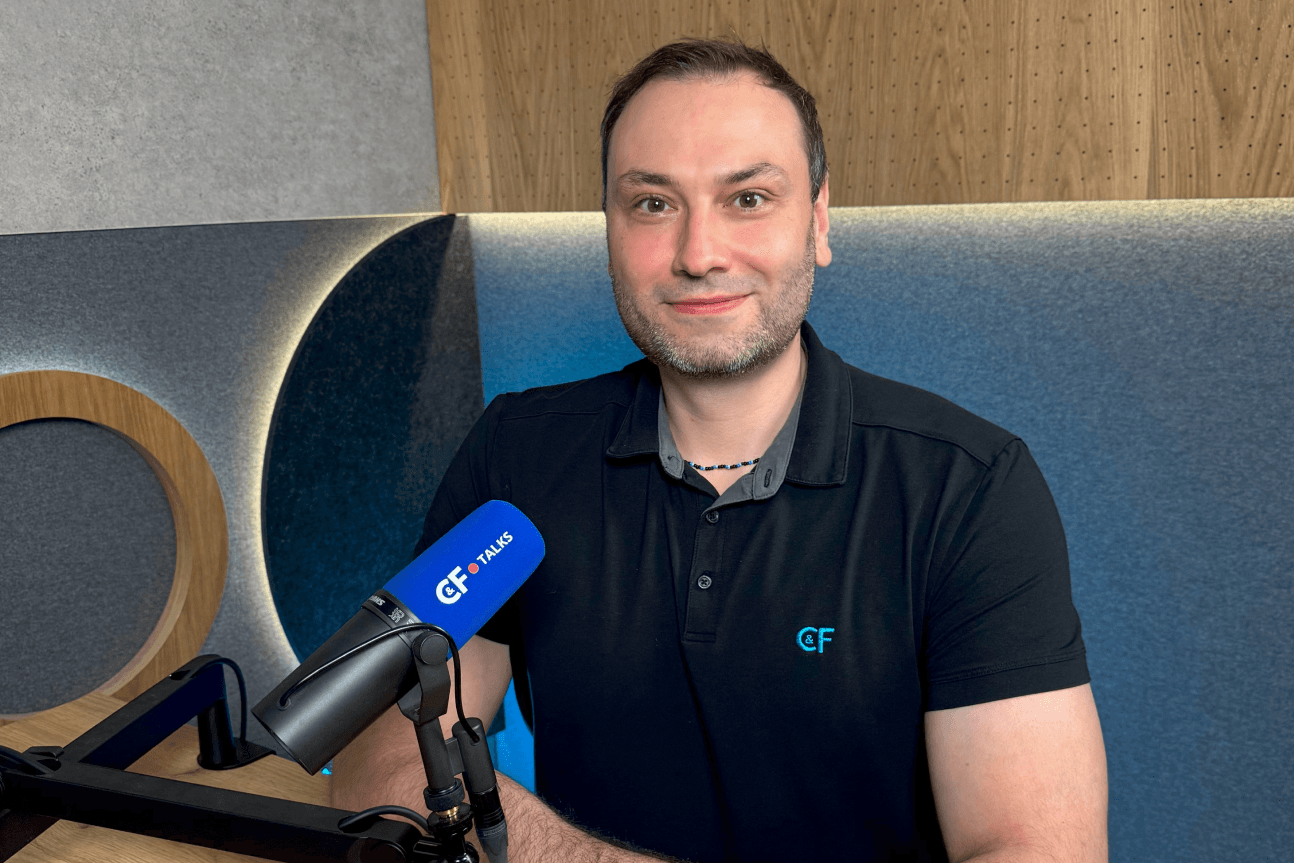

Meet the expert

Piotr Sosiński

Senior Delivery Lead, C&FPiotr Sosiński is an experienced IT and delivery leader with over 15 years in global business environments. At C&F, he focuses on applying advanced technologies to optimize supply chain operations, enhance decision-making, and build resilient processes. With a strong background in stakeholder management and complex project delivery, he bridges the gap between AI innovation and practical business outcomes.

Let’s connect

Our engineers, consultants, and experts are here to help you uncover solutions tailored to your business needs. Whether you’re looking for targeted support or planning a complex digital transformation, we’re ready to help you achieve more.